Search in Category

Filter Your Search

Brand

Brand

Shop by Category

Accessories

Excluder Dust

Aluminum Dust Excluder

The VERSA aluminum Dust Excluder protects against dirt, dust, moisture, and insects entering the valve through the exhaust port without obstructing the flow. The Dust Excluder is based on a flexible seal resting on a large-diameter seat. The design provides a tightly closed exhaust port, low breakaway pressure, large flow capacity, and self-cleaning action. It is installed by threading into the exhaust port of a directional control valve.

Product Features

- Constructed of hard yet lightweight, corrosion-resistant anodized aluminum

- Buna-N/nitrile rubber o-ring seals perform reliably with oil, fuel, and other chemicals over broad temperature range

100% Leak Tested • 10-Year Warranty

Dust Excluder

Stainless Steel Dust Excluder

The VERSA stainless steel Dust Excluders are designed for harsh environments and protect against dirt, dust, moisture, and insects entering the valve through the exhaust port without obstructing the flow. The Dust Excluder is based on a flexible seal resting on a large-diameter seat. The design provides a tightly closed exhaust port, low breakaway pressure, large flow capacity, and self-cleaning action. It is installed by threading into the exhaust port of a directional control valve.

Product Features

- Constructed of SAE 316 stainless steel conforming to NACE standard MR-01-75 suitable for direct exposure to sour environments

- Neoprene o-rings resist abrasion, weather, lubricating oils, and flame over a broad temperature range: equivale to CR

100% Leak Tested • 10-Year Warranty

DUST EXCLUDER 1"

Aluminum Dust Excluder

The VERSA aluminum Dust Excluder protects against dirt, dust, moisture, and insects entering the valve through the exhaust port without obstructing the flow. The Dust Excluder is based on a flexible seal resting on a large-diameter seat. The design provides a tightly closed exhaust port, low breakaway pressure, large flow capacity, and self-cleaning action. It is installed by threading into the exhaust port of a directional control valve.

Product Features

- Constructed of hard yet lightweight, corrosion-resistant anodized aluminum

- Buna-N/nitrile rubber o-ring seals perform reliably with oil, fuel, and other chemicals over broad temperature range

100% Leak Tested • 10-Year Warranty

Vent Screen 1/8" NPT, SST

Stainless Steel Vent Screen/Bug Screen

The VERSA stainless steel Vent Screens are threaded into the exhaust port of a directional control valve and offer effective protection against dirt, dust, and insects entering the valve with minimal effect on flow.

Product Features

- Constructed of SAE 316 stainless steel conforming to NACE standard MR-01-75 suitable for direct exposure to sour environments

100% Leak Tested • 10-Year Warranty

MUFFLER EXHAUST 1/8" STAINLESS

Stainless Steel Vent Screen/Bug Screen

The VERSA stainless steel Vent Screens are threaded into the exhaust port of a directional control valve and offer effective protection against dirt, dust, and insects entering the valve with minimal effect on flow.

Product Features

- Constructed of SAE 316 stainless steel conforming to NACE standard MR-01-75 suitable for direct exposure to sour environments

100% Leak Tested • 10-Year Warranty

Quick EXH 1/4" NPT x 3/8" NPT

Stainless Steel Quick Exhaust Valve

The VERSA stainless steel Quick Exhaust Valve is a 3/2 valve with extra large exhaust orifice, designed to be fitted directly at a cylinder port connection. The main purpose of a Quick Exhaust Valve is to get extra fast movement of the cylinder rod or valve actuator.

Product Features

- Constructed of SAE 316L marine grade stainless steel conforming to NACE standard MR-01-75 suitable for direct exposure to sour environments

- Fluorosilicone o-rings perform reliably over extreme temperature ranges and exposure to fuels, oils, solvents, chemicals and coolants: equivalent to FVMQ

100% Leak Tested • 10-Year Warranty

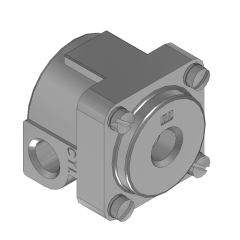

QUICK EXHAUST, 1/2", 316SS

Stainless Steel Quick Exhaust Valve

The VERSA stainless steel Quick Exhaust Valve is a 3/2 valve with extra large exhaust orifice, designed to be fitted directly at a cylinder port connection. The main purpose of a Quick Exhaust Valve is to get extra fast movement of the cylinder rod or valve actuator.

Product Features

- Constructed of SAE 316L marine grade stainless steel conforming to NACE standard MR-01-75 suitable for direct exposure to sour environments

- Fluorosilicone o-rings perform reliably over extreme temperature ranges and exposure to fuels, oils, solvents, chemicals and coolants: equivalent to FVMQ

100% Leak Tested • 10-Year Warranty

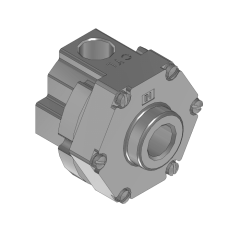

RELIEF VALVE// 316 SS// 90PSI/ 1/2" NPT

Stainless Steel Pressure Relief Valve

The VERSA stainless steel Pressure Relief Valve is designed to withstand challenging conditions in pneumatic applications. The relief pressures are factory set and tested in 5 psi (0.34 bar) increments to meet your application requirements.

Product Features

- Constructed of SAE 316 stainless steel conforming to NACE standard MR-01-75 suitable for direct exposure to sour environments

- FKM o-ring seals perform reliably with exposure to hydrocarbons or highly corrosive fluids over a broad temperature range: equivalent to Viton®, Fluorel®

100% Leak Tested • 10-Year Warranty

Relief Valve 1/2" NPT SS

Stainless Steel Pressure Relief Valve

The VERSA stainless steel Pressure Relief Valve is designed to withstand challenging conditions in pneumatic applications. The relief pressures are factory set and tested in 5 psi (0.34 bar) increments to meet your application requirements.

Product Features

- Constructed of SAE 316 stainless steel conforming to NACE standard MR-01-75 suitable for direct exposure to sour environments

- FKM o-ring seals perform reliably with exposure to hydrocarbons or highly corrosive fluids over a broad temperature range: equivalent to Viton®, Fluorel®

100% Leak Tested • 10-Year Warranty

RELIEF VALVE// 316 SS// 100PSI/ 1/2" NPT

Stainless Steel Pressure Relief Valve

The VERSA stainless steel Pressure Relief Valve is designed to withstand challenging conditions in pneumatic applications. The relief pressures are factory set and tested in 5 psi (0.34 bar) increments to meet your application requirements.

Product Features

- Constructed of SAE 316 stainless steel conforming to NACE standard MR-01-75 suitable for direct exposure to sour environments

- FKM o-ring seals perform reliably with exposure to hydrocarbons or highly corrosive fluids over a broad temperature range: equivalent to Viton®, Fluorel®

100% Leak Tested • 10-Year Warranty